DHR/AR Rheometer: Setting Up a Step (Transient) Repeated Creep Test

Overview

This test is designed to determine the resistance of asphalt binders under repeated loading simulating traffic loading. The test method includes using an oscillating shear rheometer to conduct repeated creep and recovery testing under temperature and load conditions typical of pavement condition in the field.

Rutting is caused by accumulation of permanent deformations caused by the repeated application of traffic loading. To evaluate the contribution of binder properties to the rutting resistance, repeated creep and recovery are used. By carefully selecting the loading and unloading (recovery) time periods, traffic speed can be effectively simulated or represented. By selecting a certain range of stress on the asphalt samples, different traffic loading conditions can be simulated. The accumulated permanent deformation (strain) during each cycle and the rate of the accumulation as a function of cycles provide useful information for evaluating the rutting resistance of the asphalt binders.

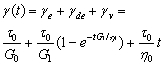

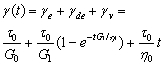

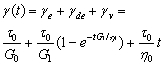

The test information is obtained from the data collected for Cycles 50, and 51 fitted by the Burger or four-element model:

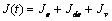

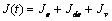

By normalizing the strain to the stress applied, the creep compliance, J, in terms of its elastic component Je, the delayed-elastic Jde, and the viscous component Jv, can be defined:

The viscous component is inversely proportional to the viscosity (Jv) and directly proportional to stress and time of loading. Calculate the inverse of the compliance Gv = 1/Jv. Gv is defined as the viscous component of the creep stiffness.

Back to top

Test Setup

To select a Step (Transient) Repeated Creep test, see Using Experimental Procedures for detailed instructions.

When you perform a Step (Transient) Repeated Creep test, the following parameters need to be chosen.

Environmental Control

Select the following environmental control parameters:

- Temperature: Maintains temperature selection throughout the test. Enter the desired test temperature, or select Inherit set point to maintain the previously-specified temperature at the start of this step. The temperature range is dependent on the configuration of your instrument and the installed environment control system.

- Soak time: The amount of time to delay data acquisition at the start of the step, typically to allow for temperature equilibration. This time is measured from the start of the step if Wait for temperature is not selected, or from the point at which the measured temperature becomes stabilized at the specified Temperature, if Wait for temperature is selected. Because of the mass of the sample, test fixtures, and environmental control systems a "soak time" (i.e., time to equilibrate at temperature) is recommended, particularly when starting steps at different temperatures. A five-minute soak time is sufficient for most samples in cases where the change in temperature is not too large.

This time is also used at each increment temperature.

- Wait for temperature: Select this option to wait until the measured sample temperature reaches the specified temperature before beginning data acquisition. If you wish to begin data collection without waiting for the sample temperature to reach the specified value, disable this option.

Back to top

Test Parameters

Set up the following test parameters.

- Choose between Stress or Torque, then enter the desired value. This parameter the specified initial step stress (torque) to be applied to the sample.

- Check the Value multiplication box if the stress or torque is to be varied during the repeated creep tests. If unchecked, the stress or torque stay constant during all subsequent creep steps.

- Multiply value by: This is the factor the intial stress or torque is multiplied by during the subsequent creep steps.

- Every n repeats: This parameter is used to define the sequence of stress or torque changes as a function of number of creep tests. N is the number of creep steps at constant stress or force before the stress or force is increased by the multiplication factor.

- Define the following parameters to complete test setup:

- Creep time: This is the extend (time) of each creep step.

- Recovery time: This is the equilibrium time to allow the recovery of the deformation at zero stress or force between repeated creep steps.

- Number of repeats: This is the total number of repeated creep tests in the sequence, independent of stress or torque changes set by the Value multiplication check box.

Back to top

Step Termination

TRIOS Software allows you to define conditions in which a step is halted ahead of its normal termination conditions (Limit checking). You can use this to ensure that, for instance, the instrument does not over speed or apply excessive strains.

Rather than running a step for a certain amount of time, you may wish to run it until stable data is obtained. You can set an Equilibrium limit (such as the viscosity value becoming constant when running a single shear with time) that will stop the currently active test.

Back to top